Very few actors, both in e-commerce and 3PL, have adapted their warehouse to have 100% of their products packed automatically. Even if you set out to have most of your range packed automatically, there will always be the odd exception when you need to have a package packed manually.

The advantage of having a package packed manually is in the craftsmanship. The disadvantage is that it takes more time. Carefully packing a package manually will never achieve the same throughput as a machine.

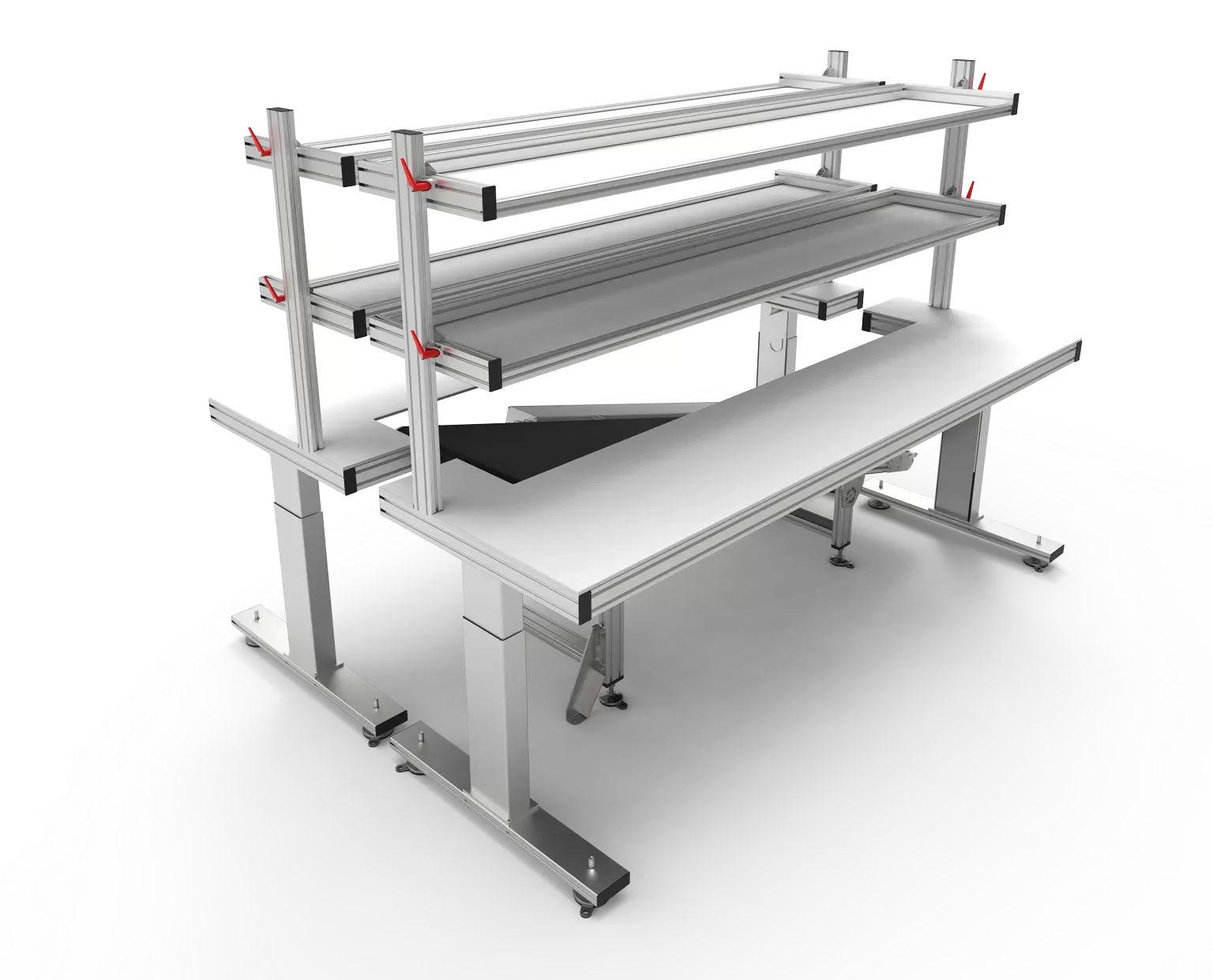

For a warehouse to maintain a high level of efficiency, as well as the manual craftsmanship, you need a well-functioning manual packing station.

The operator should be able to have goods presented in an ergonomically favourable position with suggestions from the WMS / ERP on which of type of packaging to use. By using RFID, you can collect the data needed for waybills and have it sent back to the WMS / ERP without the operator having to spend time on scanning. Checking the weight of the picked goods can quickly ensure that it matches the set target value.

Finally, the operator just has to push the package slightly forward on to the connected belt conveyor, which then carries the package to the sorting station.

The current average time for packing a parcel (without the above support) is between 45 and 60 seconds/parcel. We have been able to halve this time in many of our existing facilities. In other words, we have doubled the capacity.

Would you like to know more? Give us a call!