Pick-to-light or Pick-by-light? The two names refer to the same solution, but the process is used differently by different people.

The solution refers to a picking solution that is commonly used in warehouse and logistics operations. This also includes e-retailers and third-party logistics companies.

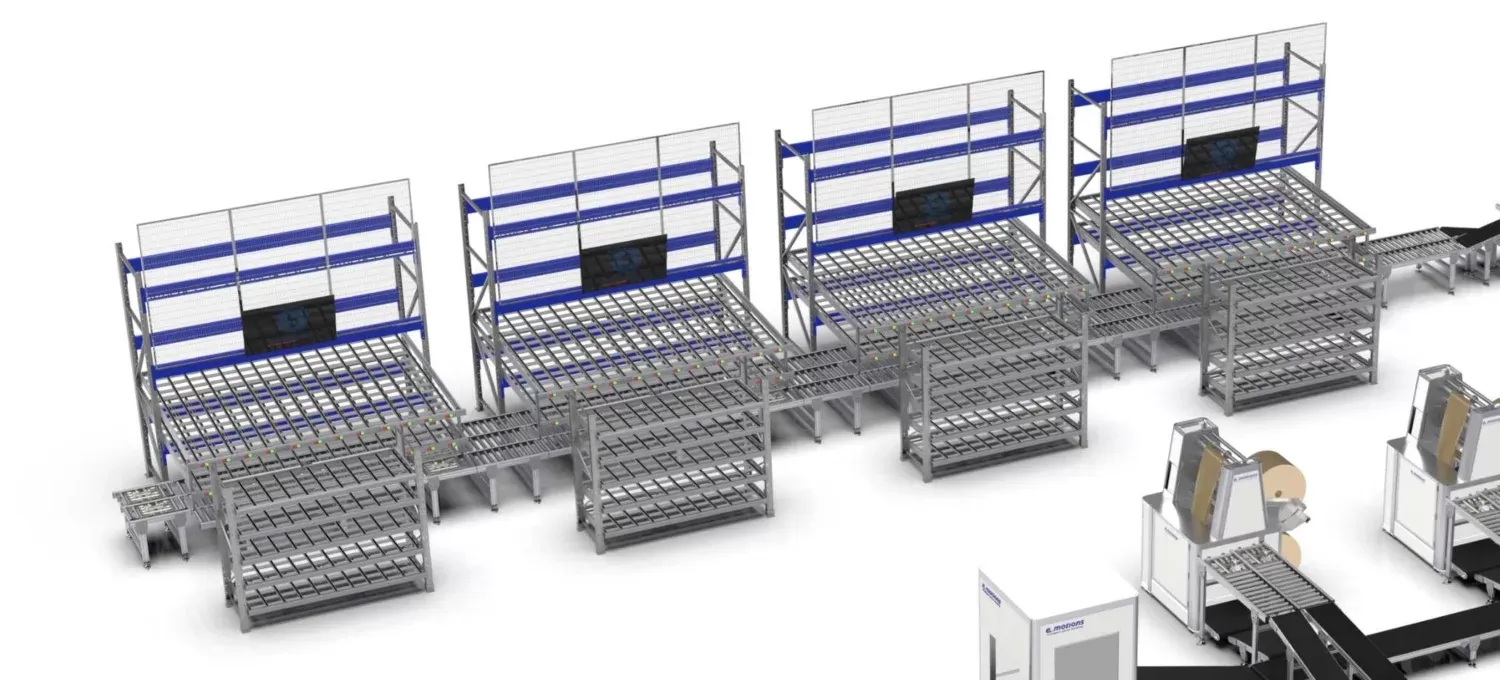

Let’s start by dissecting the term, beginning with "Pick" – We are now entering the warehouse picking process, where lights, digital displays and TV screens are used to both facilitate and speed up the picking process, rather than manual tools like pen and paper.

When the operator stands at / walks towards the designated shelf, he/she will be met by a luminous light and a display showing the specified number to be picked. By clicking on the illuminated button, the pick is acknowledged and the communication with the overlying system (WMS, ERP) updates the status to "picked".

The great advantage of a pick-to-light solution is that you always have products available, and that the solution can be combined with all types of cube systems, ASRS, vertical storage and similar.

As stock replenishment always takes place from the back, it is also a great way to keep track of products with date stamps. In a regular shelving system, the operator is required to constantly move "old" goods forward to replenish products behind.

It's hard to find a faster picking system than pick-to-light, where the FTE (Full-time equivalent) can pick up to 10 times as fast as a regular warehouse pick. Even when compared to robotic warehouses, it is difficult to find a system with a higher number of presented boxes/minute than an operator can pick with 84 available SKUs within 1 square metre in front of him/her.

A pick-to-light is mainly suitable for e-retailers with a steep curve and a long line when talking about the "pareto principle", aka the 80-20 rule In other words: If you have a small number of SKUs that account for the majority of your turnover, you want to be able to turnover these items as quickly as possible. They should be in and out of the warehouse. If this is you, you would most likely benefit from investing in a pick-to-light system. However, if this is not you, a pick-to-light system could be perceived as bulky/SKU. I.e., if the inventory transactions are roughly the same across all active items, there is little to suggest that a pick-to-light would be a solution.

A pick-to-light system is also increasingly relevant in terms of staff, as you can still ensure a high efficiency/FTE even if you have a high turnover of warehouse staff, combined with extremely variable seasonal sales patterns. In a typical warehouse, you will always have staff that move on over time, and training new or external staff can be very time consuming if the process is too complicated. When it comes to picking the amount displayed by a brightly lit lamp, the efficiency is the same regardless of gender, age or work ethic.

How can a pick-to-light solution improve your logistics? Get in contact with Jeff. He will be able to answer any queries.