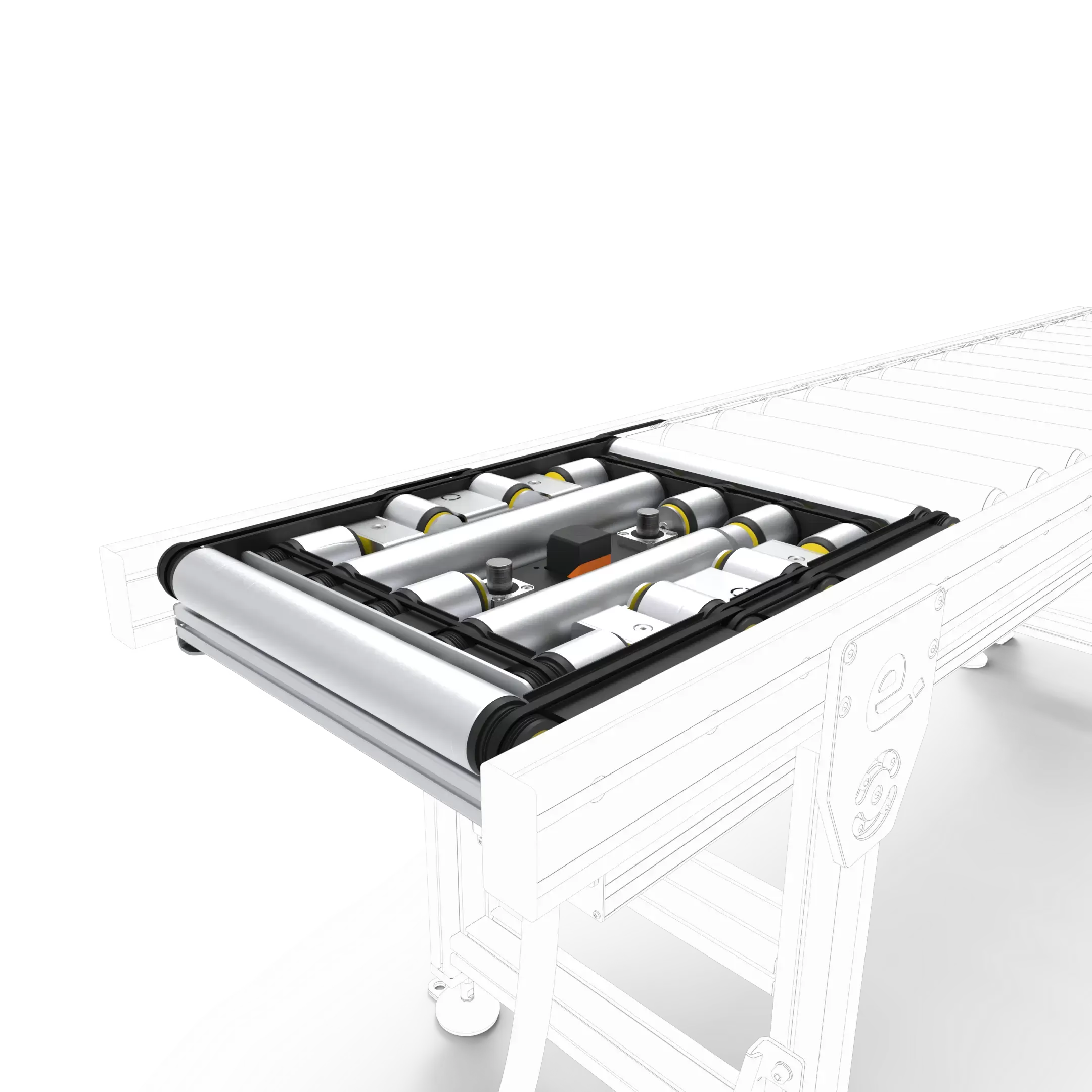

Tote stacker and De-stacker

Stacking is when we stack all the empty trays automatically. Destacking is when we release the empty trays to pick more products. In this way, you can store 200 empty trays in a space of 12 metres, instead of on a 120 metre long conveyor.

Cleverly managing space is an easy way to save money. Our stacker / destacker solution will only release trays when there is a customer order, which saves you a huge amount of space on the belt conveyors.

- Module-based

- Plug and play

- Stacker / destacker speed

- 4 sec / tray

- Stacking height

- 12 trays (Tray height 120 mm)