Roller conveyors are perfect for busy warehouses, as they can handle and transport products from the warehouse to shipping stations and various other destinations. They can also be used to manage and organise products inside the warehouse, which makes them easy to find and pick for shipment.

Roller conveyors are also effective as they can quickly and easily move large amounts of items at once.

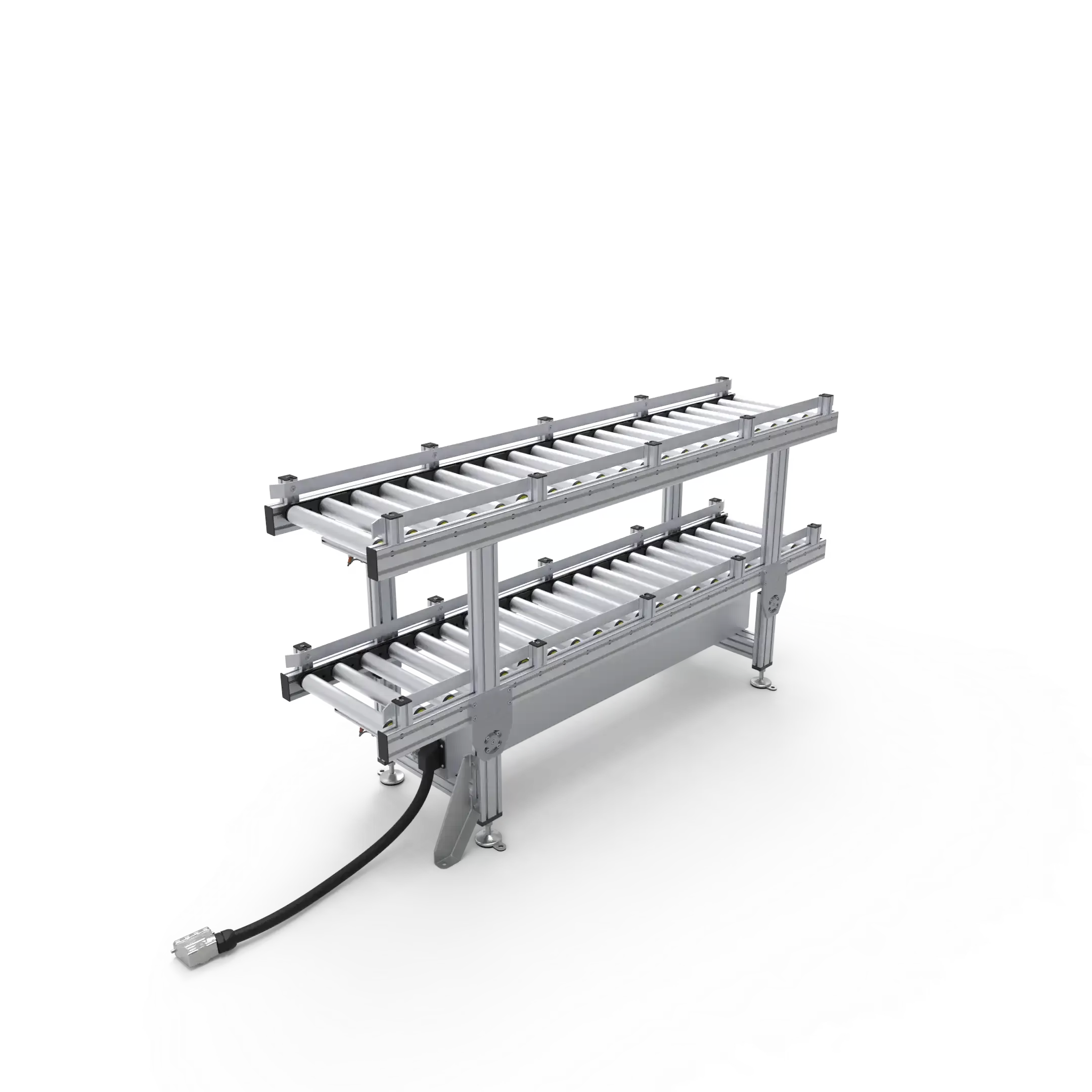

Our roller conveyors are available in a variety of designs, such as straight, curved, single track, double track and 1-2-3 track solutions, as well as in several widths. We customise the models according to your needs. Our roller conveyors will only start running when a product is placed on the belts, which significantly lowers your energy consumption. The curved models are available as single or double and in 45 or 90 degrees.

Choose from roller conveyors in various models and sizes. We tailor our proposal to your e-commerce needs. Contact us today!

Straight conveyor

Two track conveyor

Three track conveyor

Double track conveyor

Curved conveyor

In our range, you will find both unpowered and powered roller conveyors. All our conveyors are height-adjustable and stable thanks to the many fixing points. The absolute heavyweight has a maximum capacity of 2.5 tons and consists of 12 rollers. Whatever your need, we can customise the right roller conveyor solution for you and your business.

Our latest roller conveyors have a minimal footprint in length, width and height, without losing performance or stability. A high-quality standard product with a smart design. The roller conveyor is flexible and has a modular construction, which makes it easy for you to scale up or adapt your production. With an extra focus on scalability. We want your business to continue to develop and grow while the degree of automation increases. When new needs arise, we can quickly adapt the equipment.

The roller conveyors are also embedded in our automation solutions and integrated with IoT functionality for a seamless production. The roller conveyor is driven by poly-v-belts, where the motors are integrated into the rollers. This enables zone control, which means that only the current zone of the roller conveyor is activated. In that way, we can keep the energy consumption and noise level low,

which reduces operating costs and contributes to a good working environment. Zone control also allows for functions such as stacking and separation. This makes our roller conveyors an easy choice in terms of quality and efficiency.

The motorised rollers in the conveyor are driven by either individual drive stages or a combined drive stage that can handle 4 motors and 8 digital inputs or outputs distributed via Profinet®. With this solution, you can save the operational data for the motors to use in a future pre-set plan.

The roller conveyor models come in speeds between 0.17–2.01 m/s, weights up to 100 kg, widths up to 1500 mm and lengths up to 6000 mm. The roller conveyor can also be ordered unpowered without motor and with unpowered rollers. Includes a 12-month warranty with 1 shift.