Roller conveyors are perfect for busy warehouses, as they can handle and transport products from the warehouse to shipping stations and various other destinations. They can also be used to manage and organise products inside the warehouse, which makes them easy to find and pick for shipment.

Roller conveyors are also effective as they can quickly and easily move large amounts of items at once.

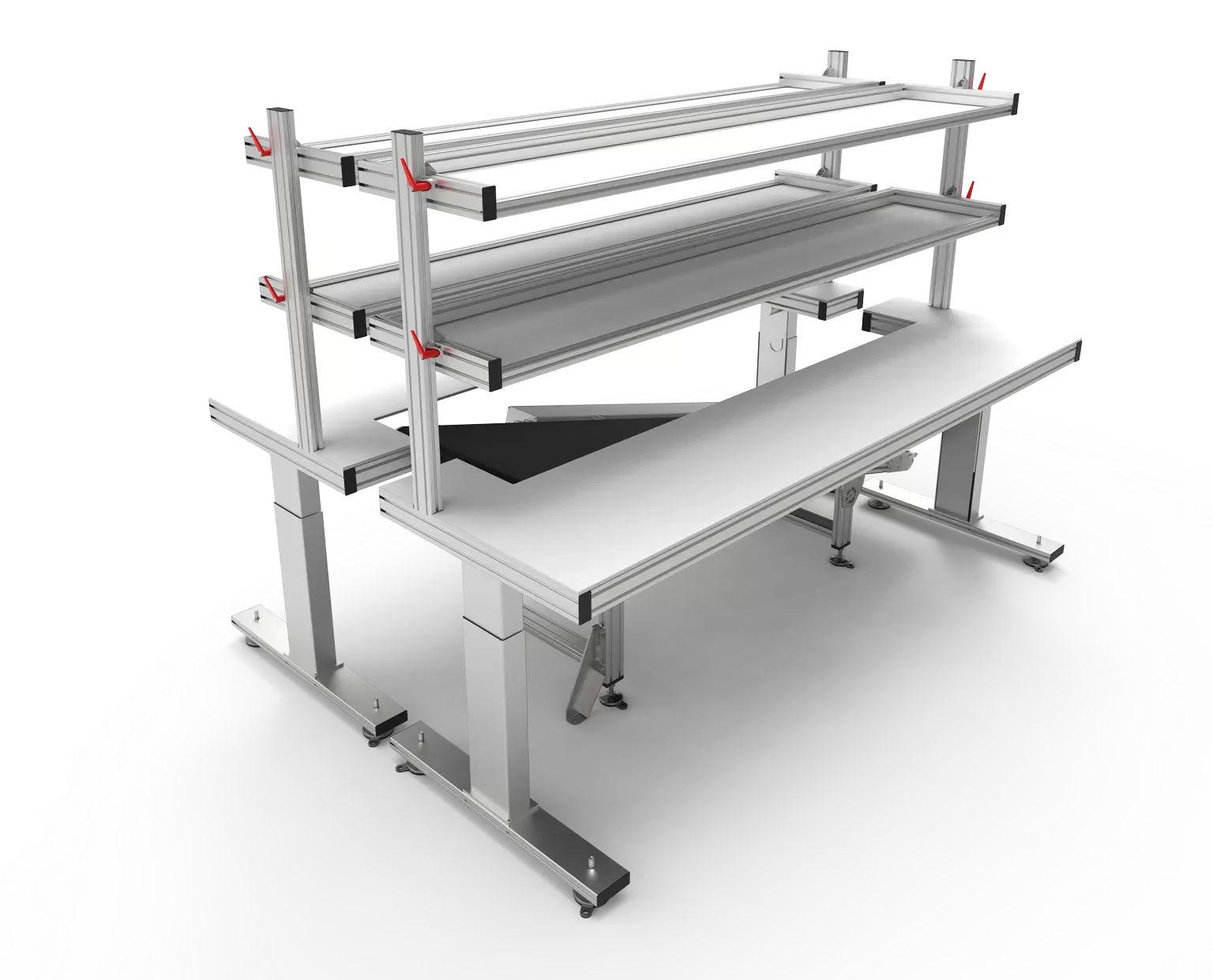

Our roller conveyors are available in a variety of designs, such as straight, curved, single track, double track and 1-2-3 track solutions, as well as in several widths. We customise the models according to your needs. Our roller conveyors will only start running when a product is placed on the belts, which significantly lowers your energy consumption. The curved models are available as single or double and in 45 or 90 degrees.

The first real bottleneck you run into as a successful e-retailer, or third-party logistician, is the package. Therefore, this is the perfect starting point in your automation journey. Over time, it is difficult for a manual packer to produce more than 50 packages/h. A packing machine, on the other hand, can produce anything from a few hundred up to thousands per hour

Regardless of which packing machine you consider best for your own business, e motions are always on hand to install and integrate them all.

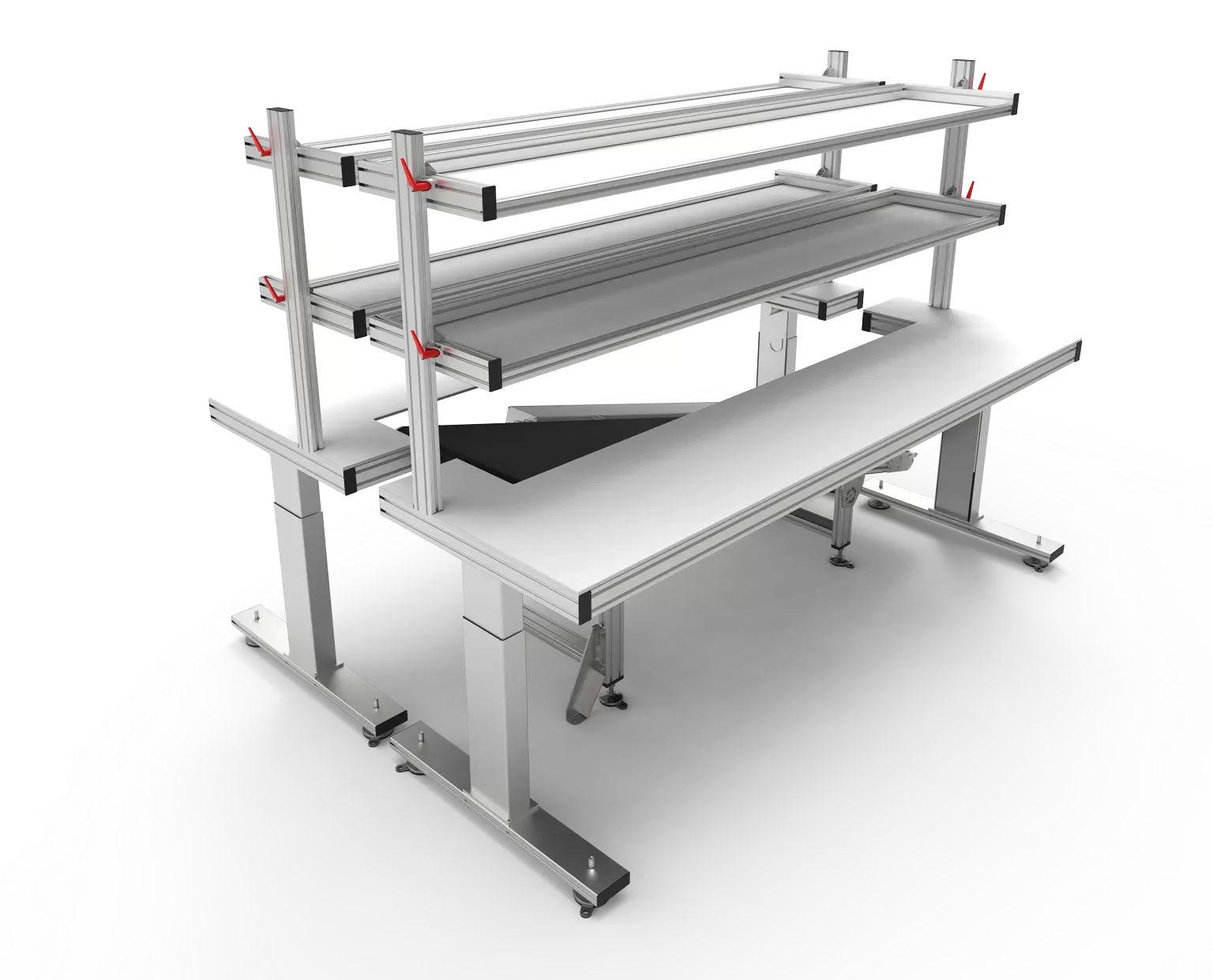

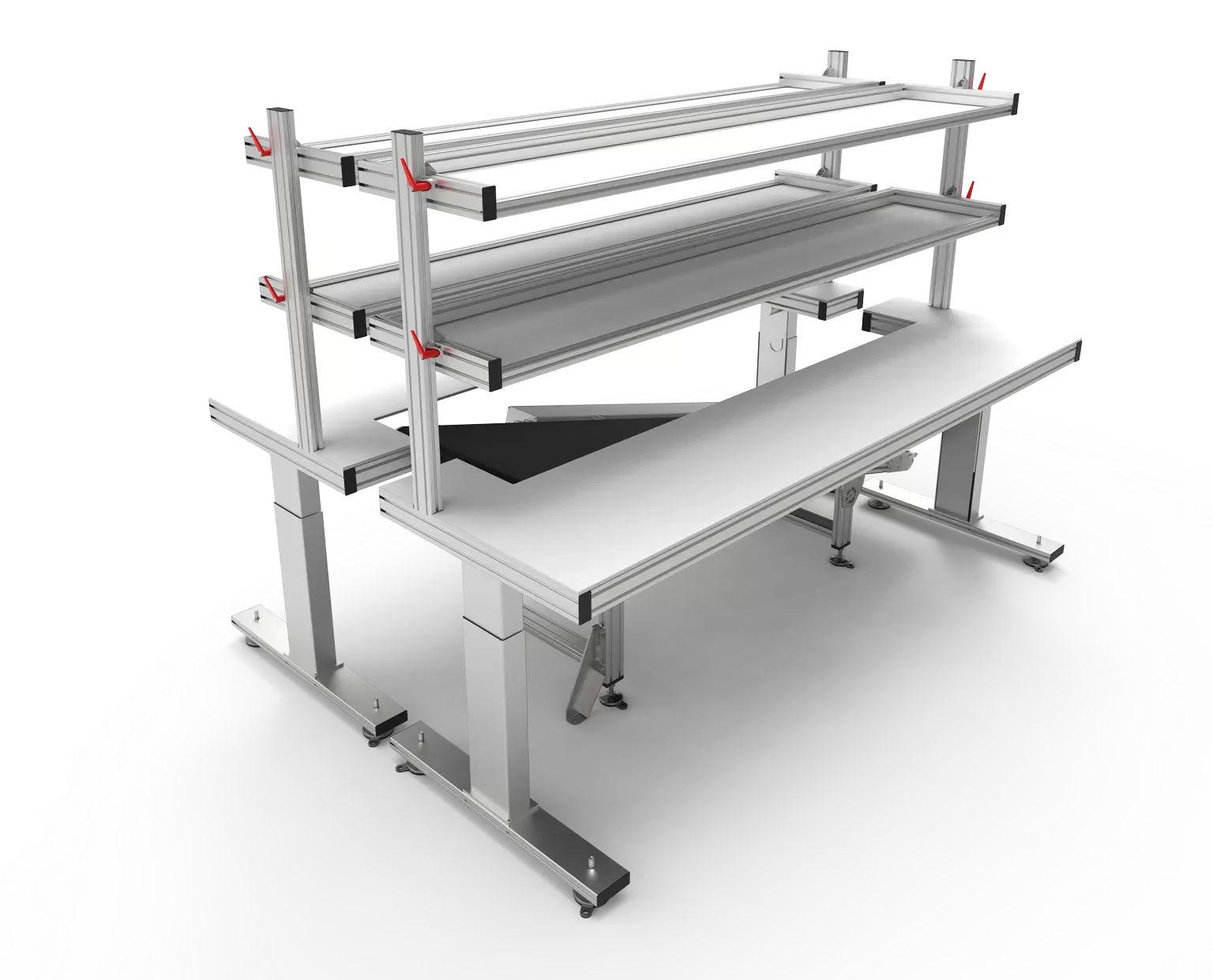

Very few actors, both in e-commerce and 3PL, have adapted their warehouse to have 100% of their products packed automatically. Even if you set out to have most of your range packed automatically, there will always be the odd exception when you need to have a package packed manually.

The advantage of having a package packed manually is in the craftsmanship. The disadvantage is that it takes more time. Carefully packing a package manually will never achieve the same throughput as a machine.

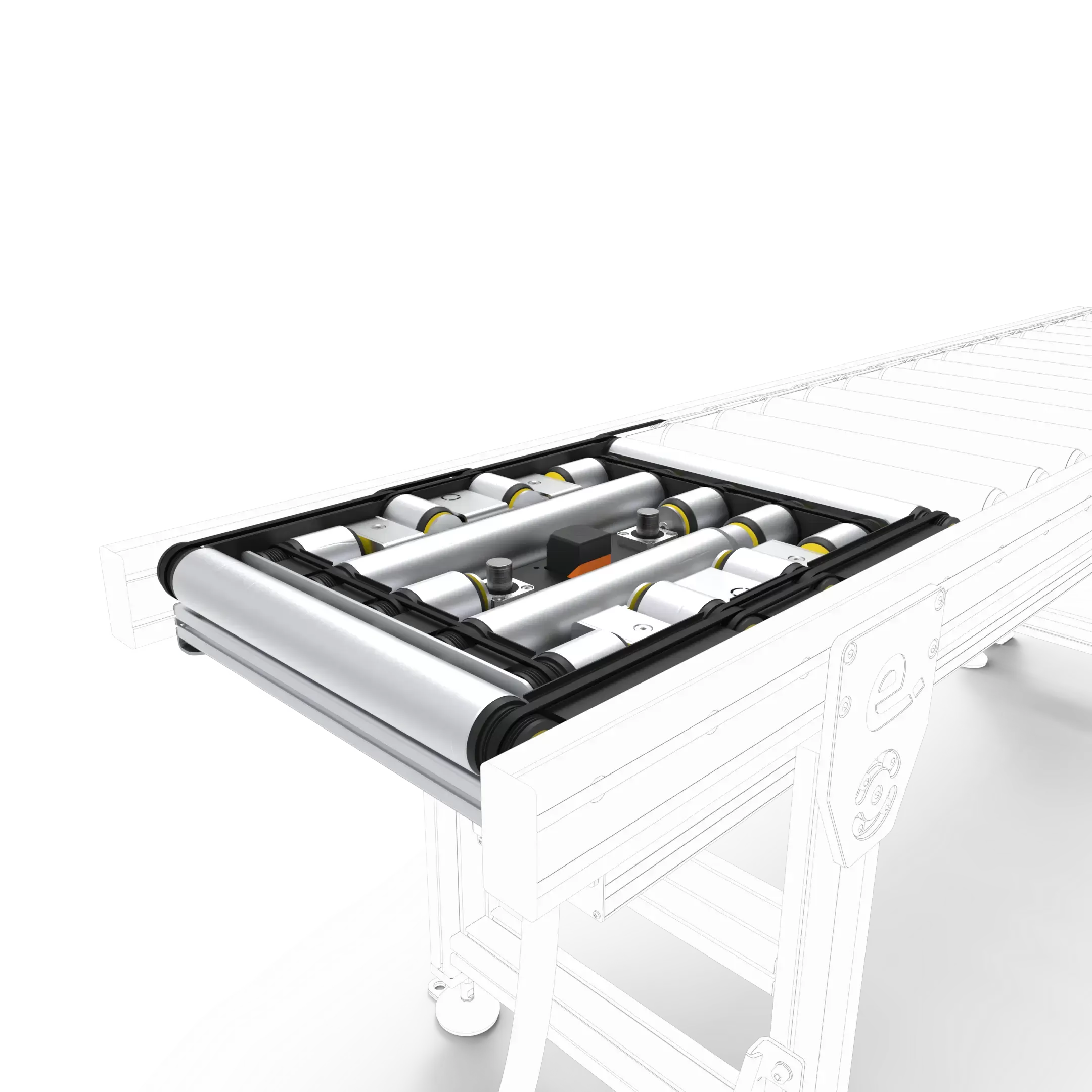

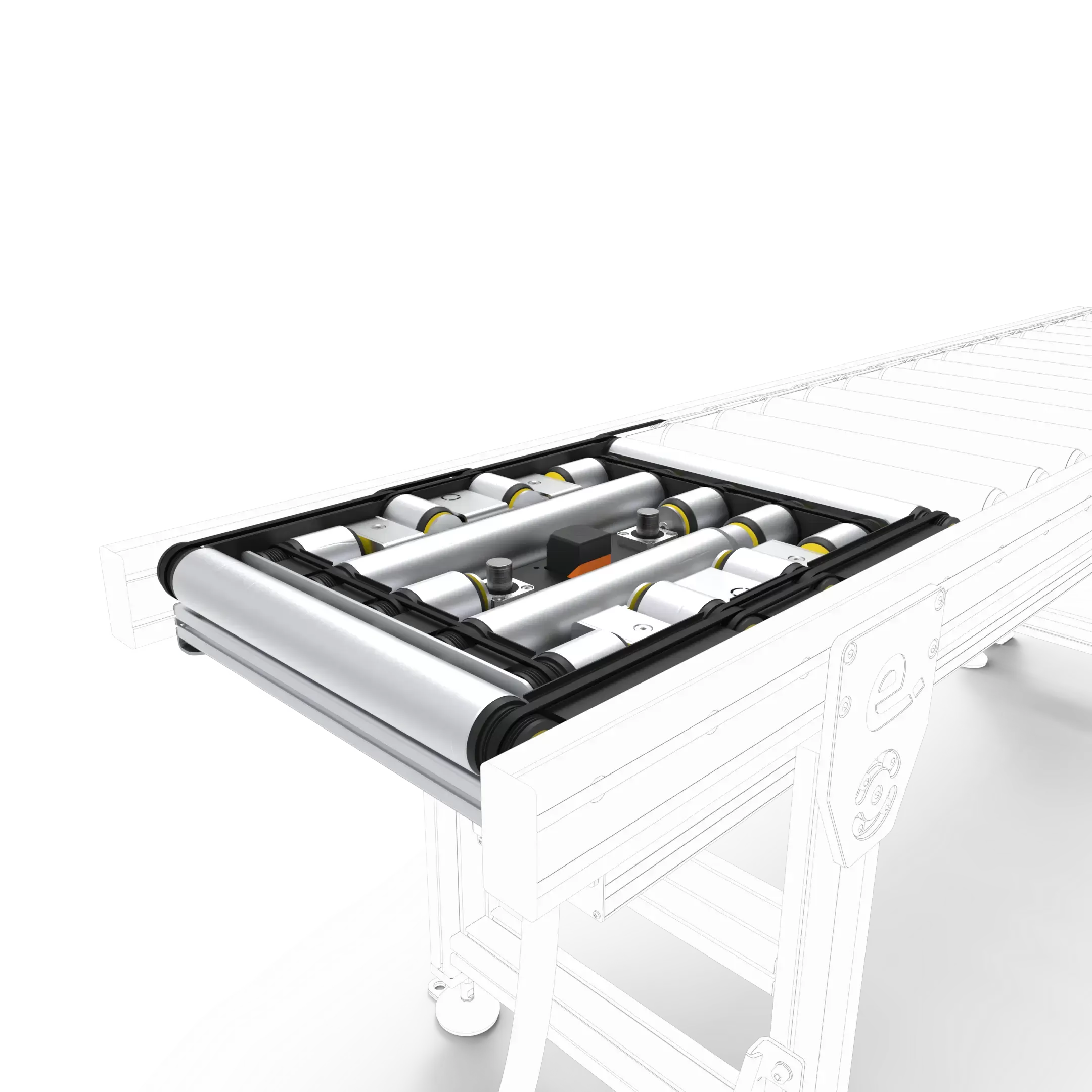

A conveyor belt transfer unit can split a stream of items into several different directions for further processing or delivery. Here at e motions, we offer an automated pneumonic transfer unit, which means it won’t require belt replacements or similar.

Our transfer unit enables staff to handle orders more efficiently and safely, while reducing the risk of damage or loss. Contact us if you are looking for a conveyor belt transfer unit. We are here for you!

We offer a broad variety of belt conveyors. Our own range is called Slimline and has been designed with durability and site efficiency in mind. We can also design and supply conveyors with larger belts and higher capacities.

Conveyor belts are always included in our complete solution, where they can be adapted to your particular flow. We also supply stand-alone conveyors for simpler solutions. With us, you get the right solution for your warehouse and logistics.

The DWS system is the brain of our automation and the reason why our parcel management solutions are so smart. By using IoT supported software, the system communicates relevant information, such as weight and dimensions, directly to and from your existing systems.

DWS stands for Dimensions, Weight and Scanning. Using IOT technology, all the intelligence is in the DWS system, which sends and receives this information from and to other equipment and your own WMS system to make everything as seamless as possible.

This user-friendly IOT communication means you never have to invest in servers or electrical power units. The DWS hub is only supplied with high voltage power, and all our automation units are connected through an IO link, both in terms of power supply and other communication.all our devices in the automation in series via IO-link. Both for power supply and other communication.

Our sorting solution is modular, which means it can be scalable in both hardware and software. We customise our sorting unit to your requirements, no matter what your flow looks like today, and we can easily scale up the entire site as your flow increases and the business grows. This makes it easy to add new customers, products or collections, as well as adapt the flow during peak order periods.

Thanks to the adaptive software, the sorting solution can be scaled up very quickly, and the IoT (Internet of Things) software allows us to access the unit from our office. In this way, we can provide a better service and offer a flexible sorting solution for all our e-commerce and logistics clients.

As your automation partner, the service performance is our responsibility. Should there be any doubt that a package is incorrectly packed, or that some information is missing, we will not sort out the package. Instead, it will immediately be sent to a point designated for errors or returned to be repacked.

Many issues can be solved by having a ready-to-be-shipped package finding its way into the right cage automatically. Just as many issues can arise if a wrongly sorted product falls from a height of two metres.

As a 3PL, for example, it is not uncommon to find products like kettlebells and champagne glasses in the warehouse. Whether it’s a heavy or delicate item, you can save yourself a lot of time, headache and money by having products sorted on a gravity roller conveyor instead.

A medium-sized installation is perfect for those who currently have automation but need to take the next step for a more seamless logistics journey. Our hardware and software can easily interact with other systems. No matter what size your warehouse is, we can help you take the next step. Contact us and receive a proposal customised for you.

Our systems can be integrated with most major WMS and ERP systems available, and we can easily start integrations with new systems. Read more about our software.

Contact us to find out how we can help your e-commerce business. Welcome to e-motions!